Consumers are looking to the UK’s OEMs and dealer networks to help them comprehend whether they should go for an electric vehicle and, if so, to ensure it meets their needs.

Like most consumers who don’t really care how an internal combustion engine works, as long as it powers their car to get them from A to B, many feel similarly about EV motors and batteries.

Yet the new and still improving EV technology does often cause some consternation or curiosity.

Battery technology is the element that typically comes under most scrutiny. Let’s unpick a few elements for further exploration.

So what are the different types of batteries and their chemical make-up?

The current most popular is the lithium-ion battery and is referred to as NMC, which is the cathode make up with N= nickel, M= manganese and C=cobalt.

The NMC is followed by numbers such as NMC 622 or NMC 811 which related to the ratios of each element e.g. NMC 622 is 6 parts nickel, 2 parts manganese, and 2 parts cobalt. What’s more, the ratios give different performance characteristics.

But there are now two viable alternative which are:

Lithium iron phosphate battery (LiFePO 4) often shortened to LFP or LFMP (if manganese added). The benefits of this battery are long lifespan, high energy density, and safety.

And sodium-ion (Na) batteries are attracting a lot of attention recently. The main reasons being that they are cheaper, safer, and more environmentally friendly. The negative is that they have a lower energy density and a shorter life span. Despite the performance challenges car makers are testing the market with these batteries whist working to improve the performance.

What are the pros and cons of each battery?

Energy Density

NMC batteries have a high energy density of 150-200 Wh/Kg. LFP batteries have an energy density of 100-150 Wh/Kg, while sodium-Ion is similar to LFP. NMC batteries have better energy density than LFP or Na batteries which makes NMC batteries better for vehicles with a performance requirement. The energy densities quoted are the focus of a lot of research and will change.

Life cycle

An NMC battery has an expected cycle life of about 2,500 to 3,000 cycles, Na around 2,000, and a LFP battery has a typical cycle life of about 5,000 cycles. LFP technology produces a significantly better battery cycle life than NMC batteries and can last twice as long.

Cost per kWh

NMC batteries are expensive because of the materials used in the battery. NMC batteries require Nickel, Manganese, and Cobalt in considerable quantity for the cathode material. LFP batteries are cheaper than NMC batteries because they use iron and phosphate as cathode materials, which are abundant and cheap. Na batteries remove lithium and Na is abundant.

Safety

NMC batteries have complex chemistries which can be the subject of a thermal incident which is made worse by the chemical reactions which fuel any fire. Therefore, improper construction or inappropriate battery use can make it catch fire or explode, which has been seen mainly with e-scooters and e-bikes. Many have home modifications or chargers which do not cut off when the device is fully charged, then overheat.

LFP batteries have a more stable chemistry, as does Na. However, research has shown that EV fires per number of vehicles is actually less than internal combustion engined (ICE) vehicles.

INSIGHT: Tackling the urgent need for sustainable battery recycling

Will EVs become easier to sell in the next couple of years?

The answer is dependent on circumstance. As confidence in ownership and charging grows more people will make the choice. They’ll have more options, too. In the next few years the technology will not change much but the choice of chemistry to vehicle application will become clearer.

The likely scenario is that NMC will go into medium to large passenger vehicles and some vans (due to the need for performance), LFP will enter service into larger vehicles of low mileage and Na initially into small family cars (due to the lower cost).

The range of vehicles will increase but battery chemistry and chargers will not change much.

The amount of infrastructure going in is considerable and the batteries are lasting much longer than expected.

What guidance can I give the customer about treating the battery so that it lasts longer?

What guidance can I give the customer about treating the battery so that it lasts longer?

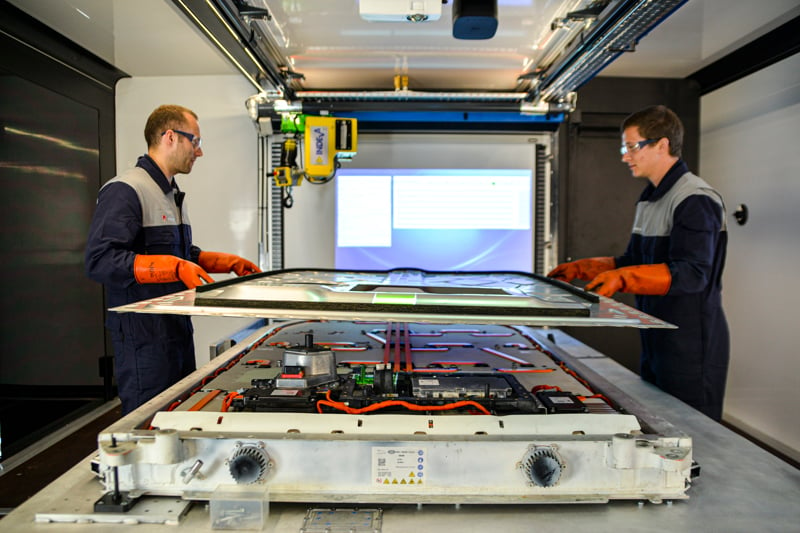

EV batteries have a built-in protection system called a battery management system (BMS) which is there to regulate activity.

The needs of the customer will determine how a car is charged. Just as many people plug their smartphone in every night at home regardless of the charge level, some might do the same with a vehicle, particularly if they’ve bought an older used EV or an entry-priced model with sub-150 mile range.

However, slow charging starting at 20% then up to 80% is deemed to be the best. This of course is great if a daily journey allows this, but a full battery may be needed for many businesses and so the 80% rule can’t apply.

These days, artificial intelligence (AI) can also be deployed to work out how much a vehicle should be charged, at what speed, and when – this is available through some charging platforms and can also charge using the cheapest energy, as the cost of electricity fluctuates over the day.

Do battery replacements need to be factored into the cost of EV ownership?

Battery replacement isn’t really a concern at present, so much so that on January 6, 2022, a Tesla Model S P85 reached an impressive mileage milestone of 1,500,000 km (932,256 miles).

If a van or car is bought new on a 3-5-year lease or PCP there will not be a problem with its performance.

Even vans, which are driven 13,000 miles annually on average, will still have have 80% of the battery’s conceivable total lifecycle left at the seven or eight year point when the warranty expires.

But until there are significant numbers of seven-year-old or older electric vans in the vehicle parc there is no absolute proof no real-world evidence. There is also no market for people to produce replacement batteries yet so this is not a question that can be fully answered.

Will EVs get cheaper?

One of the main barriers to EV take up is cost and battery supply. Last decade a lot of car companies made EV noises but only Tesla did what it said it would do. The rest dipped their toes in the water, or went off in a different direction, until they realised time was running out, governments expect action, and the lithium-ion battery was all that was on offer.

Now billions are being spent building battery cell production facilities around the world – particularly in China – so once real volume is realised the unit costs will inevitably come down. Using different chemistries for different vehicles will also reflect in the cost.

In simple terms, why foot the bill for a high performance battery for a low performance requirement.